Why Is Corrosion Protection Important?

Corrosion of steel reinforcement is one of the leading causes of concrete deterioration according to AMPP. If left unaddressed, it can compromise the structural integrity, reduce load-bearing capacity, and in severe cases lead to partial or complete failure. These outcomes not only result in high repair costs but can also pose serious risks to public safety.

Tailored Solutions for Every Environment

Freyssinet provides customized corrosion protection strategies designed around the unique needs of your structure. Whether it’s a bridge, building, tunnel, pipeline, or marine structure like a jetty or pier, we take into account your timeline, goals, and environmental conditions to recommend the most effective approach.

Our solutions target the area around the reinforcement or the steel itself and can be used to:

- Prevent the onset of corrosion

- Slow or halt early-stage corrosion

- Protect against long-term corrosion progression

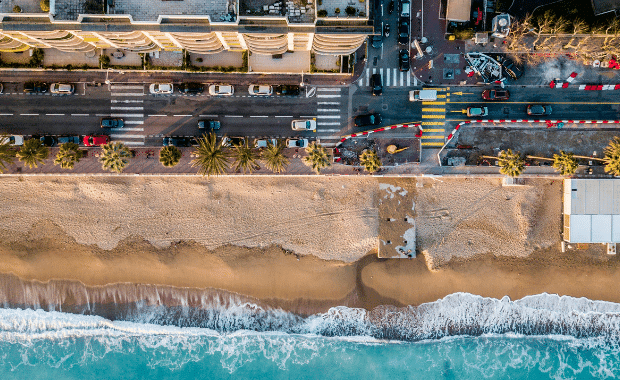

Corrosion protection against sea salt and chloride exposure.

Caltex Wharf in Australia – Copyright: F. Courbet

Safeguarding against airborne chlorides that can accelerate corrosion in concrete.

Protecting reinforced concrete from carbonation-induced loss of alkalinity in the concrete cover.

Preventing the infiltration of water contaminated with deicing salts, which can lead to corrosion of embedded steel.

A Complete Range of Services

Condition Assessment & Diagnosis

We conduct thorough inspections using a combination of non-destructive and intrusive testing methods to assess the cause, extent, and rate of deterioration. This evaluation also considers environmental severity and structural performance to determine remaining service life and load-bearing capacity.

Technical Studies

Our technical studies help identify the most suitable, long-term corrosion protection strategies based on your project’s performance goals, durability needs, budget, and timeline. Each solution is customized to ensure value and longevity.

Execution of Specialized Work

From design through to supply, installation, and system commissioning, Freyssinet delivers comprehensive corrosion protection solutions. This integrated approach ensures consistent quality, durability, and system reliability.

Cathodic Protection System Monitoring

In compliance with industry standards, we offer ongoing monitoring of cathodic protection systems to ensure continuous effectiveness. Using remote monitoring tools, we help extend the lifespan of the structure and maintain optimal protection performance over time.

Why Choose Freyssinet for Corrosion Protection?

01. Advanced Technology & Global Expertise

Our international corrosion team is actively involved in leading technical committees, including FIB, NACE International, EFC, AIPC, and ACA—ensuring we stay at the forefront of best practices and emerging technologies.

02. Certified Corrosion Specialists

Our engineers and technicians are certified in cathodic protection through recognized standards, including NACE and ISO 15257, guaranteeing a high level of technical competence and industry compliance.

03. Complete Turnkey Service

Freyssinet offers a full range of services, from assessment and design to installation, commissioning, and long-term monitoring of cathodic protection systems. We handle every step, ensuring quality and consistency throughout your project.

04. Customized Life Extension Solutions

We tailor every corrosion protection solution to meet the expected service life of your structure, aligning with your goals for durability, performance, and cost-efficiency.

+Electrochemical Treatment

This short-term, intensive corrosion protection method uses an electric field to neutralize corrosion activity. A sacrificial anode, embedded in an electrolyte gel applied to the surface of the concrete, creates an electric current directed at the reinforcing steel. A power supply regulates voltage to ensure safe and effective treatment.

Electrochemical Chloride Extraction (Foreva® CL)

-

Directly addresses the root cause of corrosion

-

Promotes the re-passivation of reinforcing steel

-

Preserves the concrete’s original architectural finish

Electrochemical Chloride Extraction (Foreva® CL)

-

Directly addresses the root cause of corrosion

-

Promotes the re-passivation of reinforcing steel

-

Preserves the concrete’s original architectural finish

+ Galvanic Protection

Galvanic protection is a well-established method for providing corrosion protection to steel reinforcement in concrete without the need for an external power source. The protective current is generated by the natural potential difference between steel and a zinc alloy anode. The zinc, being less stable, corrodes preferentially, protecting the steel and placing it in a state of electrochemical immunity.

Galvanic Anode Options - Thermal Sprayed Zinc Anode (Foreva® GP Zinc)

-

No loss of structural clearance

-

No added weight

-

One-time, efficient installation

Discrete Anodes (Foreva® Galvastar)

-

Ideal for non-uniform or congested reinforcement layouts

-

Quick and simple installation

-

No additional weight added to the structure

Galvanic Anode Options - Thermal Sprayed Zinc Anode (Foreva® GP Zinc)

-

No loss of structural clearance

-

No added weight

-

One-time, efficient installation

Discrete Anodes (Foreva® Galvastar)

-

Ideal for non-uniform or congested reinforcement layouts

-

Quick and simple installation

-

No additional weight added to the structure

+ Impressed Current Cathodic Protection (ICCP)

Impressed current cathodic protection is a highly effective method for preventing corrosion in reinforced concrete structures affected by chloride intrusion or carbonation. This system applies a controlled electrical current to the reinforcement, bringing the steel into an electrochemically immune state.

The performance of the corrosion protection system can be continuously monitored and fine-tuned by adjusting the polarization level of the steel (cathode), ensuring long-term reliability and effectiveness.

ICCP System Variants – Discrete Anodes – Foreva® V+

-

Provides in-depth corrosion protection

-

Suitable for areas with dense reinforcement

-

Works well with complex reinforcement layouts

Anodic Mesh – Foreva® CP Mesh

-

Effective for varying steel densities

-

Withstands aggressive environmental conditions

-

Can be applied in conjunction with dry shotcrete

Anodic Micro-Perforated Strip – Foreva® CP Ribbon

-

Excellent adhesion to the concrete face

-

Suitable for a wide range of reinforcement densities

-

Designed for extreme environmental exposure

ICCP System Variants – Discrete Anodes – Foreva® V+

-

Provides in-depth corrosion protection

-

Suitable for areas with dense reinforcement

-

Works well with complex reinforcement layouts

Anodic Mesh – Foreva® CP Mesh

-

Effective for varying steel densities

-

Withstands aggressive environmental conditions

-

Can be applied in conjunction with dry shotcrete

Anodic Micro-Perforated Strip – Foreva® CP Ribbon

-

Excellent adhesion to the concrete face

-

Suitable for a wide range of reinforcement densities

-

Designed for extreme environmental exposure

Corrosion Protection Solutions by Structure Type

Contact Freyssinet Today!

Thank you for your interest in Freyssinet, Inc. To discuss a specific project, sign up for our newsletter, schedule a presentation, or request other information, please fill out the form below and we will contact you shortly.